Foamy salty water after regeneration is a topic that has garnered significant attention in the scientific community, owing to its implications in various fields. This article delves into the intricacies of this phenomenon, exploring its chemical composition, foam formation, regeneration processes, and potential applications.

The presence of ions, minerals, and dissolved substances in regenerated water contributes to its unique characteristics, including its foamy texture. Understanding the physical processes that lead to foam formation, such as surface tension and gas bubbles, is crucial for mitigating or controlling this phenomenon.

Water Composition

Regenerated foamy salty water exhibits a unique chemical composition resulting from the regeneration process. The presence of various ions, minerals, and dissolved substances contributes to its distinctive properties.

- Ions:Sodium (Na+), chloride (Cl-), calcium (Ca2+), and magnesium (Mg2+) are the primary ions present in regenerated foamy salty water. These ions are introduced during the regeneration process, where salt (NaCl) is added to the water to restore its ion exchange capacity.

- Minerals:The regeneration process can also introduce minerals such as calcium carbonate (CaCO3) and magnesium hydroxide (Mg(OH)2) into the water. These minerals can contribute to the formation of scale and deposits in pipes and equipment.

- Dissolved Substances:Dissolved organic matter (DOM) and surfactants are other substances that may be present in regenerated foamy salty water. DOM can originate from natural sources or be introduced during the regeneration process. Surfactants are surface-active agents that can reduce the surface tension of water and promote foam formation.

Foam Formation

The foamy texture of regenerated salty water is a result of physical processes that occur during the regeneration process. These processes involve the formation of gas bubbles, the presence of surfactants, and the reduction of surface tension.

- Gas Bubbles:During the regeneration process, air is introduced into the water as it is agitated and pumped. These air bubbles become trapped in the water and contribute to the formation of foam.

- Surfactants:Surfactants are substances that reduce the surface tension of water, making it easier for bubbles to form and stabilize. Surfactants can be introduced into the water during the regeneration process or may be present naturally in the water source.

- Surface Tension:Surface tension is the force that causes the surface of a liquid to behave like a stretched elastic membrane. In regenerated salty water, the presence of ions and dissolved substances reduces the surface tension, allowing for the formation of more stable foam.

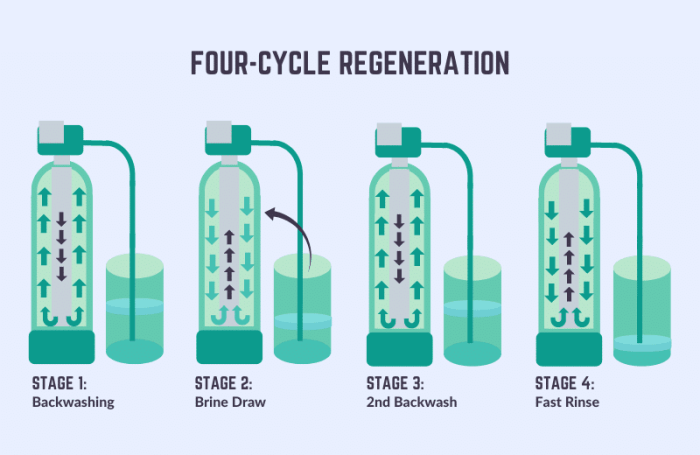

Regeneration Process

Water regeneration is a process used to restore the ion exchange capacity of water treatment systems. This process involves passing the water through a bed of ion exchange resin, which removes impurities and replaces them with ions.

- Ion Exchange:Ion exchange is the primary method used for water regeneration. In this process, the water is passed through a bed of ion exchange resin, which contains charged beads. These beads attract and exchange ions with the water, removing impurities and replacing them with desired ions.

- Reverse Osmosis:Reverse osmosis is another method used for water regeneration. In this process, the water is passed through a semi-permeable membrane, which allows water molecules to pass through while rejecting impurities.

- Distillation:Distillation is a process that involves boiling the water and collecting the condensed steam. This process removes impurities from the water, as the impurities are left behind in the boiling water.

Implications and Applications: Foamy Salty Water After Regeneration

Foamy salty water after regeneration can have various implications and applications depending on the specific context and industry.

- Beneficial Applications:Foamy water can be beneficial in applications where aeration or agitation is desired. For example, in aquaculture, foamy water can increase oxygen levels in fish tanks.

- Problematic Applications:Foamy water can be problematic in applications where it can interfere with processes or equipment. For example, in industrial settings, foamy water can cause foaming in boilers and cooling towers, leading to reduced efficiency and potential safety hazards.

- Industries and Situations:Foamy salty water is encountered in various industries and situations, including water treatment facilities, desalination plants, and industrial processes involving water regeneration.

Mitigation and Control

There are several methods available to mitigate or control foam formation in regenerated water.

- Reducing Surfactants:Surfactants are the primary cause of foam formation. Reducing the presence of surfactants in the water can help mitigate foam formation.

- Adjusting Water Composition:Adjusting the water composition, such as by reducing the salt content or adding anti-foaming agents, can help reduce foam formation.

- Anti-foaming Agents:Anti-foaming agents are chemicals that can be added to the water to break down foam and prevent its formation.

Quick FAQs

What factors influence the stability and longevity of foam in regenerated water?

The stability and longevity of foam in regenerated water are influenced by factors such as surface tension, gas bubble size, and the presence of surfactants. High surface tension promotes foam formation, while smaller gas bubbles and the presence of surfactants contribute to its stability.

What are the potential implications of foamy salty water after regeneration?

Foamy salty water after regeneration can have both beneficial and problematic implications. In some applications, such as wastewater treatment, foam formation can aid in the removal of contaminants. However, in other applications, such as industrial processes, foam can hinder efficiency and cause operational issues.

What methods can be employed to mitigate or control foam formation in regenerated water?

Foam formation in regenerated water can be mitigated or controlled by reducing the presence of surfactants, adjusting the water composition, or employing anti-foaming agents. Additionally, optimizing the regeneration process to minimize the introduction of foaming agents can be effective.